Welcome back to part 3 of the Forecasting & Demand blog series for Inform ERP. In our last blog, we explored the Critical Inventory and Projected Purchase Order (PO) modules. Today, we’ll dive deeper into three categories of demand—Recurring, Sporadic, and Unusual—and discuss how to manage each effectively. Let’s get started!

Understanding Different Demand Types

The Projected PO is a powerful tool, but not every product is sold or purchased the same way. This brings us to three demand categories you need to be aware of: Recurring, Sporadic, and Unusual. Each type requires different management approaches to ensure you’re stocking the right amount of inventory.

Recurring Demand

Recurring demand refers to products that you sell consistently, meaning you’ve sold these items for at least 8 out of the last 12 months. Products in this category make up about 20% of your inventory but are responsible for around 80% of your sales—a classic example of the 80/20 rule.

How Recurring Demand Works

Inform ERP assigns products a formula based on sales data. This process happens automatically when you close your month-end accounts receivable. The system evaluates demand per warehouse and assigns one of eight available forecasting formulas to ensure accurate projections.

Formulas

- Average: Factors in each month equally (e.g., 12-month and 3-month averages).

- Weighted: Puts more emphasis on recent months (e.g., 5-month weighted and last-month heavy).

- Seasonal: Looks at seasonal trends to predict future demand (e.g., seasonal, seasonal weighted, 5-month seasonal, 5-month seasonal weighted).

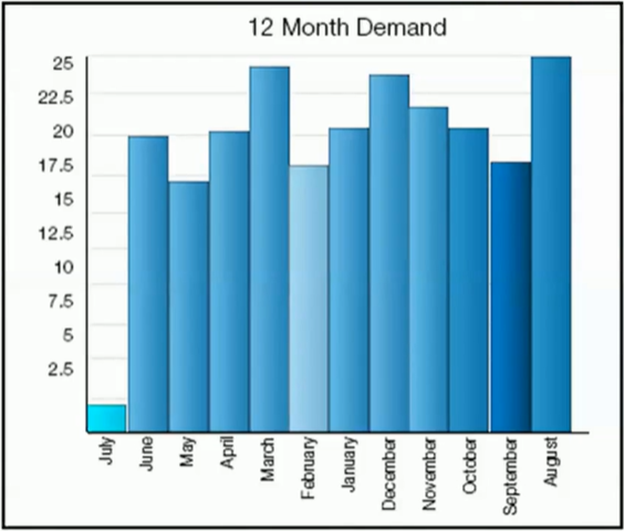

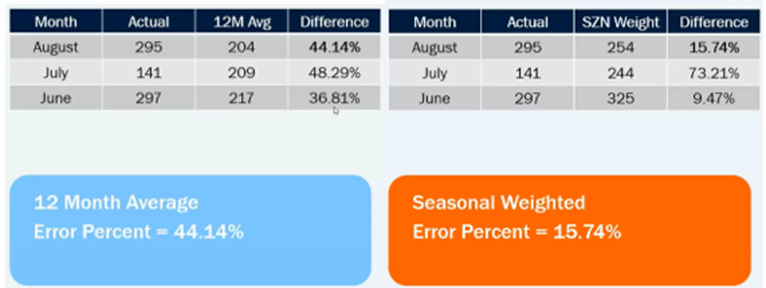

Example of Recurring Demand

For instance, the 12-month average gives you a consistent demand outlook, but in a case where your product is impacted by seasonal trends, the seasonal weighted formula might provide more accuracy. Inform ERP runs through all available formulas to find the one with the lowest error percentage for each item.

Imagine you have steady sales for a product from June to August. Using the 12-month average formula, you may find that the projection aligns well with your actual demand, but switching to the seasonal weighted formula may further fine-tune the projection for the current market.

Sporadic Demand

Sporadic demand applies to products that don’t sell consistently, making them harder to predict. You might sell an item once in one month, then not again for three to four months.

Sporadic items make up about 80% of your inventory. While they’re difficult to forecast, Inform ERP uses the mode and median values to analyze sales patterns. If you sell the same quantity repeatedly, the system uses the mode, and if not, it uses the median to determine reorder quantities.

Managing Sporadic Demand

- Max Stock Quantities: For sporadic items, you’ll want to set up a maximum stock quantity to avoid overstocking. You can also set an expiration date for the max quantity, allowing you to reevaluate and adjust it after a certain period.

- Inform ERP factors in hit/cost-based multipliers to help you avoid tying up your budget in high-cost, low-sales items.

Example of Sporadic Demand Management

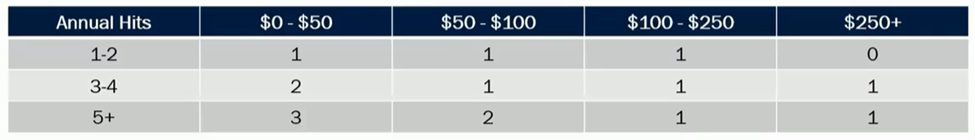

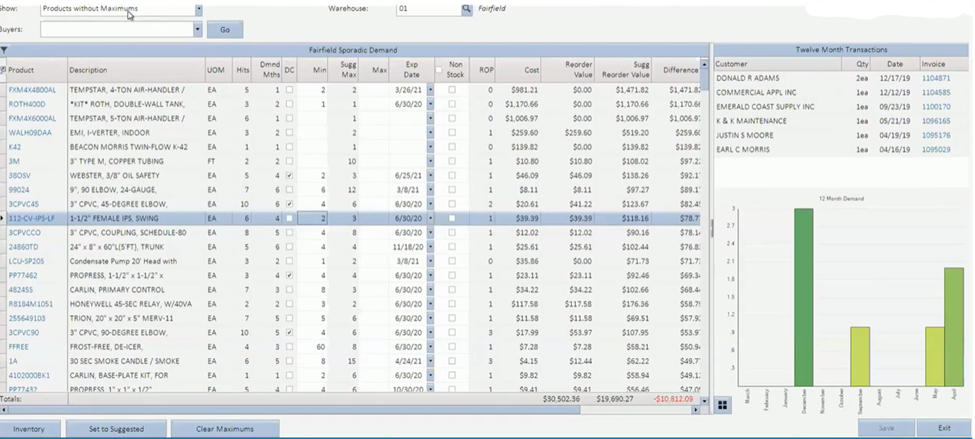

You will encounter similar tables to the one below in Inform ERP.

Let’s say you sell a floor scrubber, valued at $250+, once or twice a year. Since it’s an expensive item, Inform ERP will advise that you don’t stock any since we don’t want to tie up your money. If you sell 3 – 4 floor scrubbers, then Inform ERP will tell you to purchase one.

On the flip side, if you sell a cheaper item valued from $0 – $50 sporadically, like a copper fitting, Inform ERP might recommend keeping a small stock on hand, since it won’t significantly impact your inventory value.

Unusual Demand

Unusual demand refers to one-off spikes that can happen to both recurring and sporadic items. For example, a customer may place a bulk order that greatly skews the demand for a product, making it appear higher than usual for that month.

Handling Unusual Demand

Inform ERP helps you identify and adjust for unusual demand spikes. When an anomaly occurs, you can manually adjust the forecast to ensure future projections aren’t impacted by the one-time surge in demand.

Example of Unusual Demand

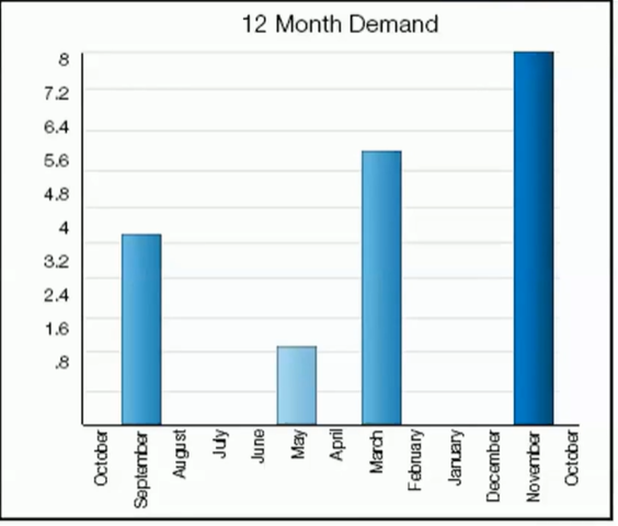

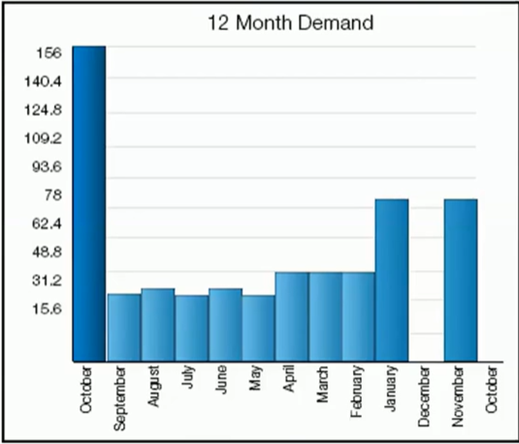

Take a look at the graph above and consider a product that typically sells around 35 units per month but jumps to 150 in one month. Inform ERP will alert you to the spike, allowing you to manually adjust the projected demand for that month, so your forecasts stay on track.

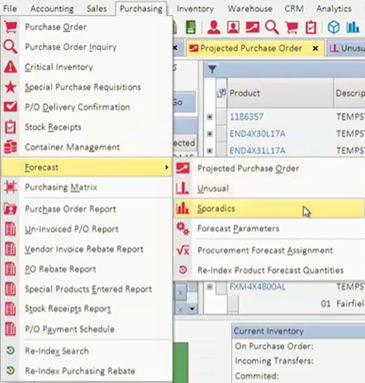

Maintaining Sporadic & Unusual Products

Inform ERP gives you the tools to fine-tune maximum stock quantities and adjust for unusual demand, ensuring your inventory levels stay aligned with actual demand trends. Unusual and Sporadic Demand can be found under the Purchasing menu > Forecasting section. We recommend you maintain these screens on a weekly or monthly basis. By managing these screens, you take a proactive approach to fine tuning and instilling confidence in the accuracy of your projections.

Sporadic Demand

The Sporadic Demand screen allows you to see all of the sporadic products that don’t have maximums. On this screen, you will assign product maximums to ensure that you stock the correct number of items.

You can review transactions from the past 12 months and adjust maximum stock levels based on actual data. If the suggested maximum stock doesn’t look quite right, you can manually adjust the maximum to whatever makes sense for your business. We also recommend you set an expiration date for the future so it can be reevaluated. If the product becomes a recurring item, then you can rely on the forecasting formulas to calculate the stock quantity. You will set the maximum stock on a per-warehouse basis. It can also be filtered by buyer, product line, and vendor.

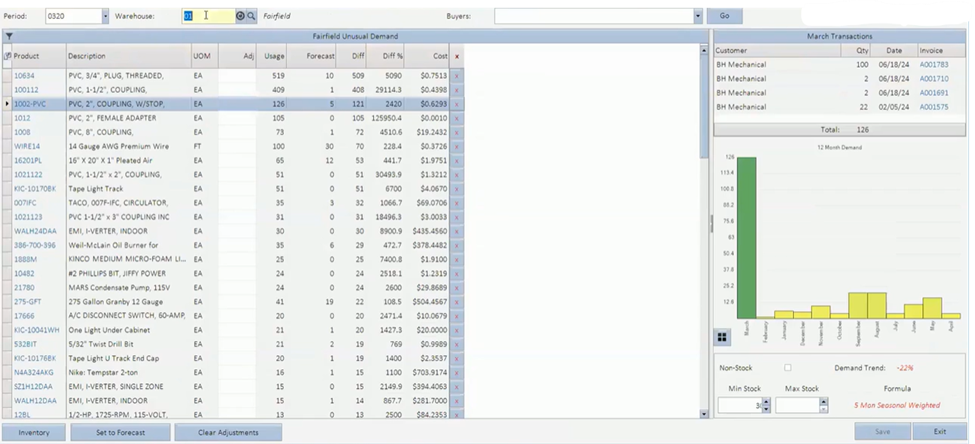

Unusual Demand

Similarly to the Sporadic Demand screen, you will identify the products with unusual demand spikes using transactions from the past 12 months at each warehouse and make manual adjustments to keep your projections as accurate as possible.

In the image above, you can see that the demand has typically ranged from 10 – 25 items, but in March, there was a spike in demand of 126 items. Inform ERP recommends you adjust the Forecast to 5 items for this period. If you don’t think this is an accurate number, you can override it in the Adj. column and make the determination yourself. This ensures Inform ERP uses more realistic and accurate numbers based on your business needs.

Come Back Next Week!

In today’s blog, we explored how Inform ERP helps businesses manage three distinct demand types: Recurring, Sporadic, and Unusual Demand. Understanding these demand types ensures your inventory stays optimized, minimizing overstock and stockouts.

Next time, we’ll dive deeper into tracking inventory results in Inform ERP. You’ll learn about turns, sales / inventory KPIs, inventory ranking KPIs, and pivot tables to unlock deeper insights into your operations. Having a clear view of your inventory health is essential for long-term success, so don’t miss it!