Kiwiplan: Packaging Automation Made Easy

Future-proof your business: Get one packaging solution to automate it all.

Change is inevitable.

Anyone in the business world knows this to be an absolute truth. However, no one knows what’s going to instigate change or exactly how things will change. And the arrival of a new federal administration raises a host of questions about what changes, if any, could be on the horizon.

Future-proofing your business against change is a must, and one of the best ways to do this is through enhanced automation. Discover how Kiwiplan can provide just that. With more the 15K machines connected using Kiwiplan software, this industry-leading ERP and MES solution is the only system purpose-built for the packing industry.

Industry-Leading Manufacturing Software

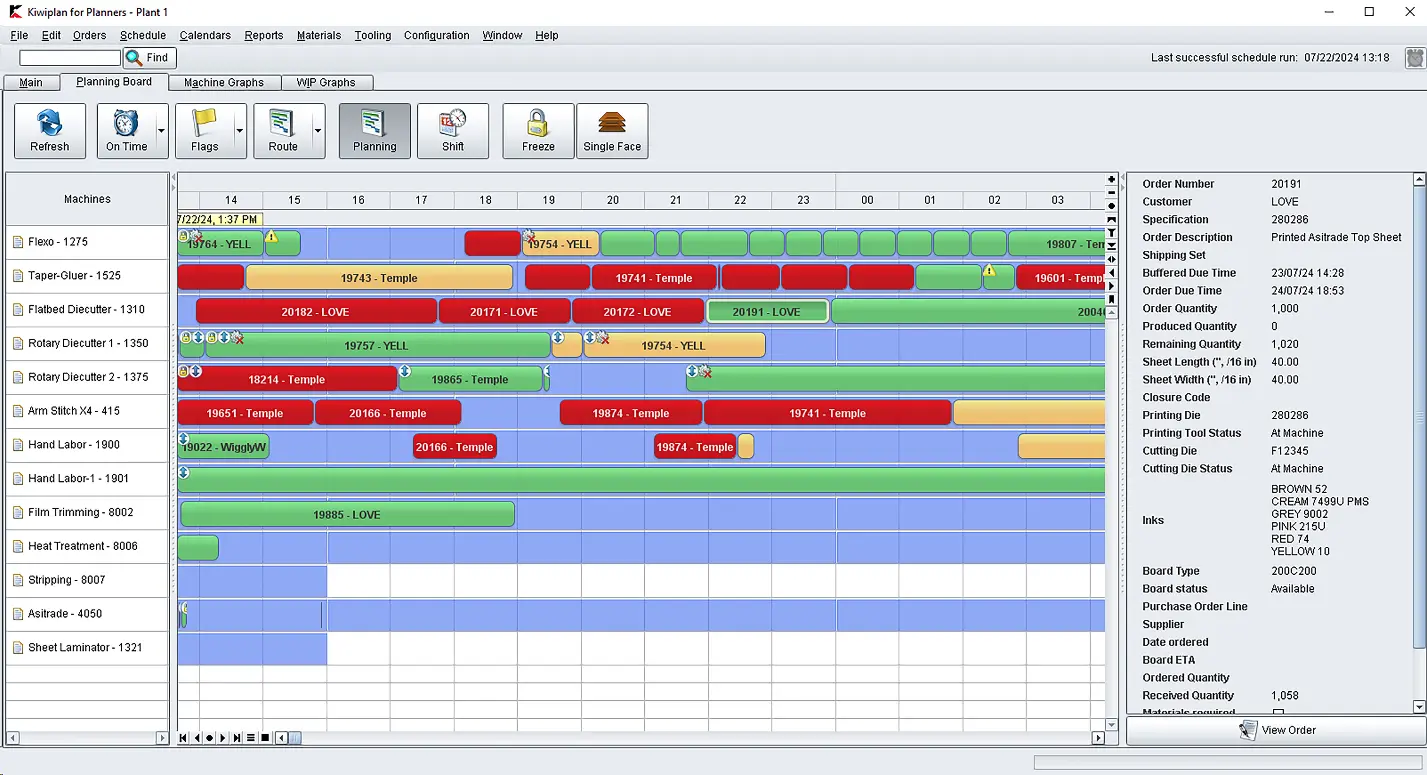

From sheet and box plants to display and specialty packaging manufacturers, Kiwiplan, Advantive’s integrated ERP and MES solution, empowers packaging companies with digital, industry-leading capabilities.

- Maximize throughput and daily square footage with 24/7 automated tracking and scheduling.

- Minimize delays and increase efficiency by integrating shipping and production planning.

- Improve on-time delivery and reduce waste and work-in-progress with advanced automation.

- Ensure Capable-to-Promise by “Booking on Blue.”

- Maximize labor efficiencies and visibility with streamlined and standardized enterprise-wide processes.

Count the Benefits.

Increase throughput and trailer utilization by up to 20%

Improve efficiency with 24/7 automation

Decrease work-in-progress by up to 25%

New Sets & Kits Feature

Sets or kits are multiple pieces made of corrugated and non-corrugated materials that need to be assembled, glued or fitted into a final product. Each set of materials are tracked in different locations within the Kiwiplan software.

Due to the different tracking methods, it can be difficult to make sure all these pieces are available at the assembly points of the route (aka the pack out) at the same time.

But now with Kiwiplan’s new sets screens, you can see the order status of corrugated pieces, as well as the inventory numbers of non-corrugated pieces on a single screen.

Box Plants & Sheet Feeders

For more than 40 years, Kiwiplan has been providing solutions for box plants and sheet feeders around the world with more than 500 corrugators using our solutions. As the leading provider of corrugator scheduling software, we are the only solution to provide fully automatic 24/7 scheduling.

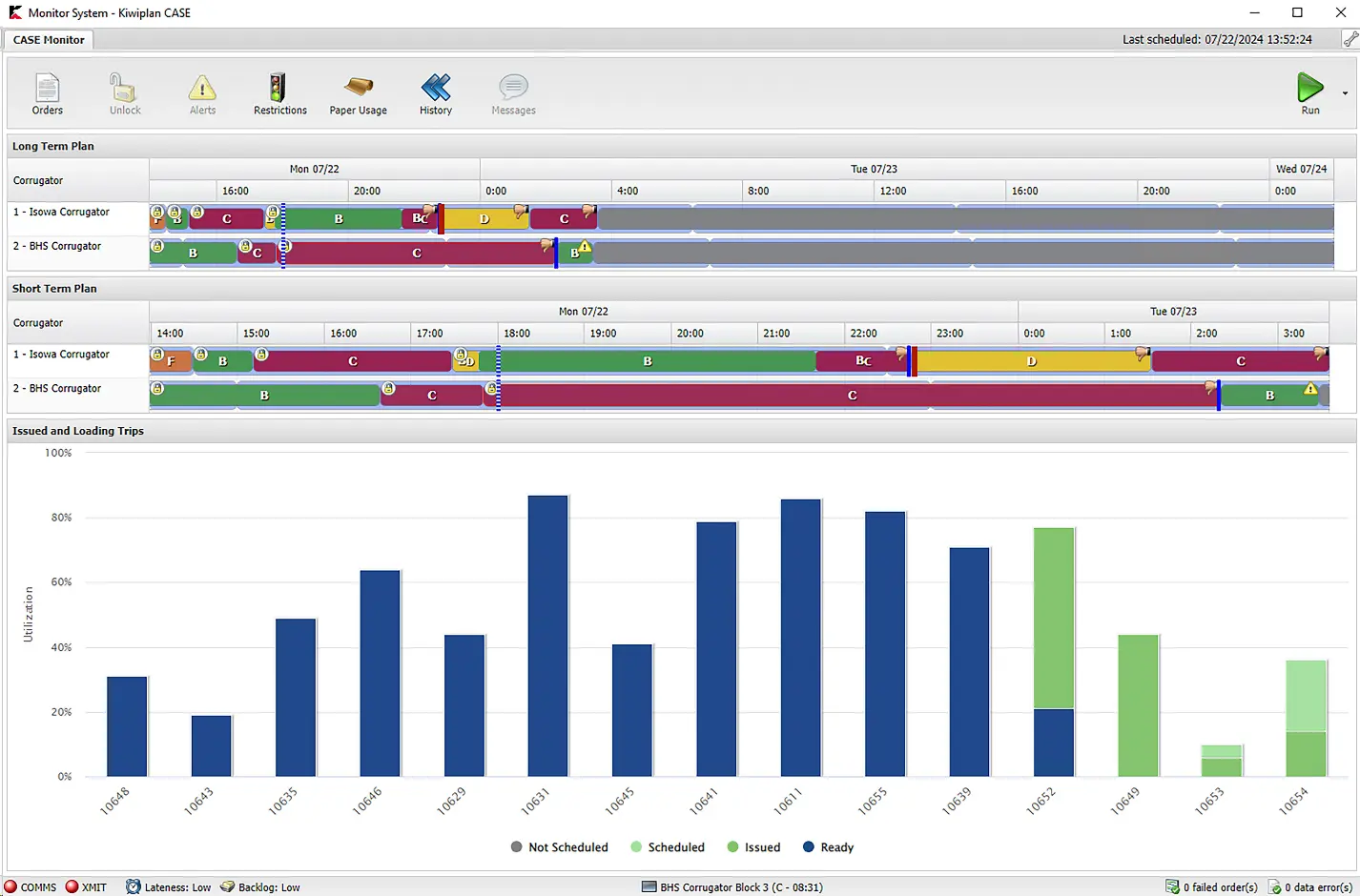

With our innovative Continuous Automatic Scheduling Environment (CASE) solution, you can easily minimize bottlenecks and manual entry by automatically updating corrugator schedules based on product changes or delays. Our intuitive CASE solution automatically plans 90 days out every 15 minutes, continuously producing the most cost-effective schedules. It also provides comprehensive reporting for enhanced strategic planning and operational improvements.

Combined with our Roll Stock System and industry-leading Corrugator Scheduling solution, Kiwiplan provides world class automation and visibility for sheet plants and sheet feeders.

Sheet Plants

Over the past 5 years, Kiwiplan has focused on helping sheet plants overcome their biggest challenges. Our new sheet plant system provides the most accurate data collection tool available on the market.

Kiwiplan’s Machine Data Collection solution gives your operation access to real-time data to reduce downtime, identify opportunities, and drive performance – from setup start time and job finish time, to setup waste and downtime details.

Our Truck Scheduling System reduces shipping costs and puts you in the driver’s seat. Whether you ship 2 or more than 30 trucks a day, TSS automates and maximizes the efficiency of your shipping process. Our industry-leading TSS solution automatically plans loads every 15 minutes for all jobs due in the next 90 days – making sure loads are continuously optimized for space. The intuitive system provides proactive alerts as soon as shipping issues are identified, allowing you increase on-time deliveries with real-time data.

Display and Protective Packaging

What’s new with Kiwiplan? We’ve enabled advanced systems to manage your protective packaging needs, such as wood and foam converting.

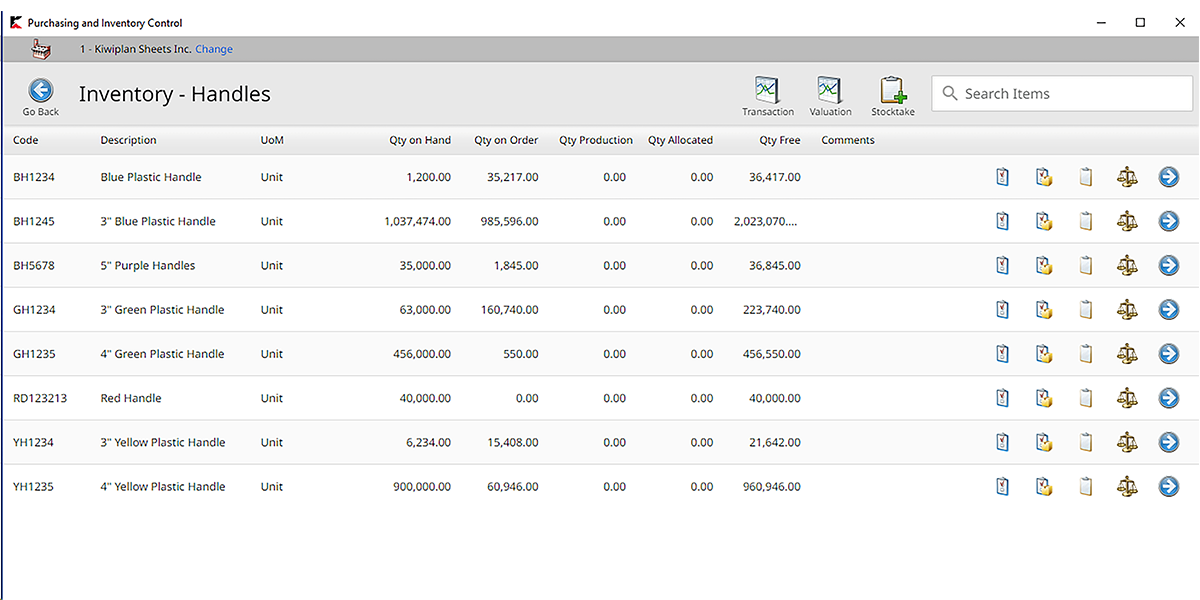

Our new Purchasing and Inventory Control System, PIC, displays real-time inventory for any material in the manufacturing process, increasing visibility and streamlining processes across your organization.

• Digitally managing inventory from purchase through allocation.

• Managing inventory across multiple plants and locations.

• Maintaining accurate inventory with stock take and inventory adjustment features.

• Improving accuracy with 3-way reconciliation for sheet purchases (ordered, BOL, received).

Additionally, we’ve streamlined managing sets, kits, and pack-out projects. You can now view the status of the entire set, including all corrugated and non-corrugated components, on a single screen! This feature also allows you to easily create templates for scalability and share stock components for easier set creation.

Watch a Demo

Learn how Kiwiplan’s scheduling and tracking capabilities can give you true visibility into your operations.

Digital is all the craze these days, but it is only as good as the software you are using to automate you shop floor. If you can’t connect to your software because it is in the cloud and your internet is spotty, it can’t do much for you. If your software doesn’t offer truly dynamic scheduling capabilities that allow you to automate and integrate your processes, what value are you really getting? Discover how Kiwiplan can help you:

- Reduce lost units and costs by easily tracking WIP and finished goods.

- Adjust loads automatically to keep your trucks optimized and full.

- Reduce downtime and increase on-time delivery by integrating shipping and production planning.

What to Expect

- Free 20-minute call with a product expert

- Live demo tailored to your industry requirements

- Discover what products best fit your needs

- No games, gimmicks, or high-pressure sales pitch