The year was 1988, and I found myself standing in a sumptuous conference room with nearly 700 attendees at the iconic Hotel del Coronado. I was attending a four-day conference on quality led by Dr. W. Edwards Deming himself. It was my first professional trip outside of Seattle where I worked as a newly employed statistician at the Boeing Company. And I was sweating.

I was engaged in a face-to-face, statistical argument with none other than my idol, Dr. W. Edwards Deming—the father of modern statistical quality control methods. The room was oddly quiet, and I could feel hundreds of people watching and listening.

We were debating his use of a statistical tool in his book, “Out of the Crisis.” My stance was that the statistical analysis he had used was erroneous…and I was way out on a limb. Deming was the man. He was nearly 90 years old and possessed vast quality expertise. I was just a fresh-out-of-school, 23-year-old statistician. Bringing this issue up could turn out badly. I knew it, and I was feeling the heat.

At first agitated, Deming listened patiently, then positively engaged me in discussion like a professor would with a student. We parried back and forth our different statistical opinions about the analysis. Soon, Deming looked up at me from his chair. Eyes wide with surprise, he stated emphatically, “young man, you’re right!”

Then, much to the agitation of those who wanted time with him, Dr. Deming and I huddled around my pad of paper, and he generously provided precious minutes of his time to bestow upon me both professional and statistical advice. It was an act of generosity and kindness that I remember to this day, and I am forever grateful for the time spent with such a great man.

As a result of that experience and my great respect for Deming, I’ve been itching to discuss one of my favorite topics for a while: Deming’s 14 Points for Management. Since college, I’ve admired Deming’s work and consider him a giant. His impact on the world of quality and manufacturing was (and still is) profound. He was many things in the course of his life, including an engineer, a professor, and management consultant, but especially, he was a quality visionary.

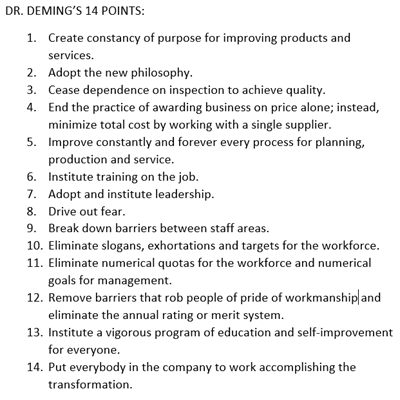

Not only is he known for his 14 Points for Management, but also his foundation of thought he called the “System of Profound Knowledge.” I can’t cover all 14 points in one blog, so I’ll see what I can fit here and continue with the list in additional blogs. Along the way, we’ll talk about something else that is near and dear to me: InfinityQS quality intelligence software solutions. Please join me for the ride.

Quality is at the Heart of it All

Before I dive into the first group of his 14 Points in this opening blog, I should summarize Dr. Deming’s overall philosophy: He taught that “by adopting appropriate principles of management, organizations can increase quality and simultaneously reduce costs (by reducing waste, rework, staff attrition, and litigation while increasing customer loyalty). The key is to practice continual improvement and think of manufacturing as a system, not as bits and pieces.”

And, coincidentally, that is essentially what InfinityQS—and our quality intelligence software—is all about: helping our clients to increase quality and customer loyalty while reducing costs and waste.

Purpose and Philosophy

Deming’s first two of 14 points are:

- Create constancy of purpose

- Adopt the new philosophy

It’s no surprise that these two points are listed as his number 1 and 2 points, respectively. The reason? Deming was famous for exhorting management to embrace change and the long-term focus of forever improving quality and service. To do so creates a solid foundation for business success.

Adopting the philosophy of a quality-oriented organization can support any management team’s goal to transform their business. Seeking ever-improved goods at a lower cost helps everything to fall into place. The most respected companies in the world are not ones that create cheap, low quality products. Instead, organizations committed to product quality and customer and employee loyalty are the ones that garner the lion’s share of industry respect.

Changes that Make Sense in Modern Manufacturing

Which changes can you make to your organization that make the most sense in terms of manufacturing in today’s highly competitive markets? On to Dr. Deming’s point number three, “Cease dependence on inspection to achieve quality.” We all know that a basic premise of total quality management (TQM) is that quality control is integrated into production processes as an integral part of everyday operations—not something considered special or out of the ordinary. Organizations need to shift to “building quality in” to their manufacturing processes rather than attempting to “inspect it in.” Ideally, when quality is integrated into processes, data collections at known strategic points along the production line should be all that is required to validate quality. And that’s where we step in.

InfinityQS quality intelligence software, as I mentioned in an earlier blog, Shifting Manufacturing Quality Paradigms, “provides manufacturers with the capability to have data collection and visibility across the entirety of an enterprise.” Our software “provides quality improvement experts at the corporate level (from anywhere around the globe) the ability to sort, slice, and dice data anyway they want from across plants, across departments, across the enterprise, across regions.” When your data comes directly from your production line, and you can dissect and analyze it any way you wish across the entire enterprise, you are provided critical information that can truly build quality into your operations.

Acceptance Sampling

Point 4: “End the practice of awarding business on price alone; instead, minimize total cost by working with a single supplier.” The main idea here is to minimize variation in supplies and raw materials. Deming emphasized single-source suppliers because it forces organizations to work closely together with suppliers for the good of both companies. Also, utilizing a single supplier eliminates additional sources of variation (i.e., the same products being supplied by multiple suppliers).

A great way of sorting the best and worst suppliers is by using the unique and atypical capabilities of our software’s acceptance sampling features. As I mention in a previous Acceptance Sampling blog, acceptance sampling “helps manufacturers minimize inspection costs, manage risk, and prevent off-quality product from entering their production processes.”

If you want to move to single-source suppliers, you must understand which ones have the highest quality levels. You will need to know which ones produce products with the least variation. And you can do that with our unique acceptance sampling features. If you work with a supply chain of any kind or size, using both statistical process control (SPC) and acceptance sampling can prove to be a game-changer for your quality results.

“Acceptance sampling says that when a specific number of the sample fails, the collective lot fails. If the number of failures is less than the ‘reject’ number defined by the acceptance sampling plan, then the lot is accepted. Pass-fail. Yes-no. Accept or reject.” If you’re a manufacturer using multiple vendors, you can use our unique analysis methods with your acceptance sampling data to analyze how vendor quality changes over time, help vendors improve their products (which helps you), determine which vendor is providing the highest quality products (which also helps you), and determine where you can single-source. Doing so enables companies to award vendor business based on quality levels as well as price.

I think that Deming’s contention with this point is that there is a greater net cost benefit to establishing long-term relationships in a supply chain rather than chasing lower prices. Bravo.

Constant Improvement

The next Deming point is my favorite: “Improve constantly and forever every process for planning, production, and service.” This is the essence of what we offer here at InfinityQS.

Constant improvement is a fundamental part of TQM—that is, makingcontinuous improvementa part of youreveryday business life.

InfinityQS believes that continuous improvement should be the goal of every manufacturer. The best path to continuous improvement we know is through storing all the quality data you collect in a centralized repository, where it can be aggregated and analyzed (again, across the enterprise, if you wish), and turned into actionable information—from which you can make strategic decisions and prioritize the improvements you want to make.

You can plan over the next several quarters or years exactly what it is you want to attack in order to make the improvements you need to make to be successful and highly competitive—not just in the short run, but also in the mid-term and in the long run.

Enough for Now

So, let’s stop there for now…we’ll continue on with more of Dr. Deming’s 14 Points in our next blog. So far we’ve looked at the first five points: creating constancy of purpose for improving products and services, adopting that philosophy in your organization, changing your outlook and use of inspection in your production processes, changing your organizational mindset regarding your supply chain, and making constant improvement a priority…forever.

Please come back and join me for the rest of the series.

- Read Part 2 of this series (points 6-10)

- Read Part 3 of this series (points 11-14)

Take advantage of the technology at your fingertips today: contact one of our account managers (1.800.772.7978 or via our website) for more information.