Standardization. Is that a dirty word to you? Is that something you consider “unattainable,” and therefore not worth discussing? Is standardization the pot of gold at the end of the rainbow? What is it? Why is standardization important for manufacturers? And what are the benefits of standardization for your organization? Let’s discuss.

In general, the role of standardization in manufacturing is almost always positive. But maintaining manufacturing standardization can be difficult.

I’m here to tell you that standardization in manufacturing isa good thing. And worth the effort. Manufacturers discovered long ago that standardizing the way your organization operates leads to increased profitability and cuts down on all sorts of problems.

So, I started thinking of the importance of standardization in what we do here at InfinityQS with our customers.

The Benefits of Standardization in Manufacturing

The advantages of standardization are many. These are the top of the charts for me:

- Deployment a Breeze – a standardized system is faster to deploy. When everything is standardized (naming conventions, software, etc.), your deployment becomes (sort of) lather, rinse, repeat.

- Maintenance to Dream About – a standardized system is much easier to maintain. When your system is standardized, you make a modification once and it applies to other processes, or data collections, or whatever.

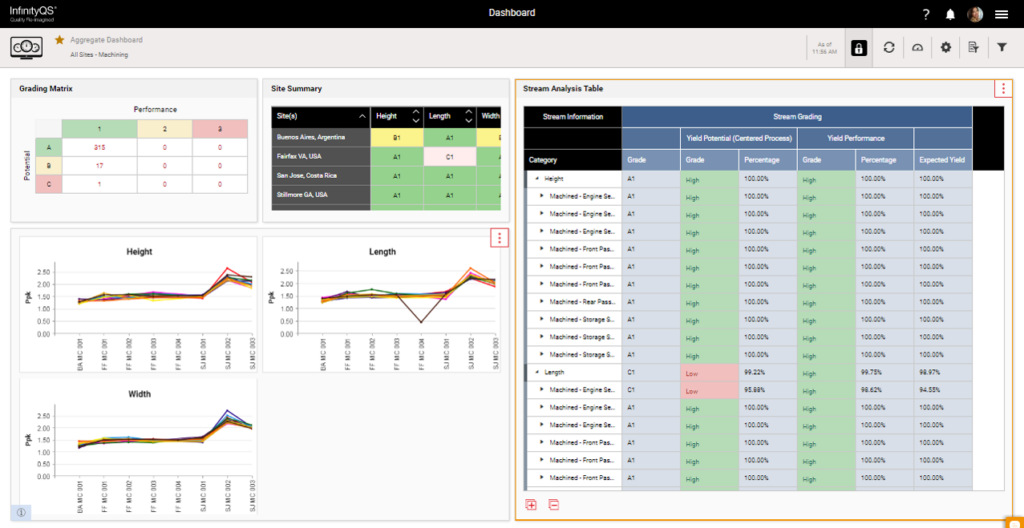

- Hubble-like Visibility – a standardized system in manufacturing gives you visibility across sites to make the kind of comparisons you otherwise would not be able to make. The Hubble space telescope could see unimaginably far into space. With standardization across your enterprise, you can see across that enterprise. And that’s priceless.

- Cloud Power – a standardized system in the cloud is much less costly. No servers to stand up, maintain, or protect; a single, unified data repository (which alone is worth the work of standardization); and easy access for users from all types of devices.

What Does “Standardization” Mean?

Why is standardization important in manufacturing? It’s essential in any system,

and is especially important to an enterprise platform like InfinityQS software. And the term has a few meanings (which I alluded to earlier), depending upon your focus:

- Naming conventions—making sure parts, features, processes, and more are named the same in every department or shift. Standardizing your naming conventions saves a lot of troubles down the road. It’s great when everyone has a common language to use when referring to the myriad components involved in your manufacturing operations. This saves time and eliminates confusion.

- Standardization also means making sure that all facilities are using the same system, be it InfinityQS ProFicient™ or Enact®. Standardizing software products makes sense for many reasons, not the least of which is collaboration: since everyone has the same tools and capabilities, teams can freely share information. When shop floor operators learn something new about the software, they can share it with others. And your IT staff will thank you: purchasing and maintaining a single system reduces their burden. It’s a headache they don’t want…or need.

- Within the software, standardization means making sure everyone is using the same functionalities in the same way. Making sure that aspects of the software are used in the same way guarantees that you’re all speaking the same “language.” This cuts down on confusion and inefficiency.

- Looking at the results of measurements in the same way is critical. Measurements are expected to give reliable results. If the ways in which the various parts of your organization view measurement results differ at all, then the decisions you make and your plans moving forward—solving issues, planning changes, allocating resources, etc.—are compromised, and made more complicated and difficult.

A lot goes into standardization in manufacturing—and there are a lot of ways to look at it and implement it within your organization. How do you talk about process performance? Do you use Pp/Ppk? Yield? Percent out of specification? Often, we hear things like, “Well, we do it this way here in the main facility, but our other site does it another way.”

This is often a by-product of things like software acquisition, previous quality issues, or employee turnover, wherein the previous regime purchased a system or did things one way and the new regime purchased something completely different and does things in a new, different way. The opportunities for mismatching—as you can imagine—are endless. Standardizing how you talk about performance means everyone is on a level playing field, which is important for buy-in at all levels. Everyone understands the benefits of data-driven decisions; everyone also wants those decisions to be made fairly.

Your Internal Differences Matter, But Don’t Let Them Thwart Standardization

Often, when we are deploying our software, we learn that two entities within an organization collect data in different ways. Perhaps a quality lab has a specific piece of laboratory equipment, and it spits out a particular piece of information; while in another setting, since they do not deal with the same laboratory equipment, it spits out slightly different information.

Or, perhaps the two labs use different methodologies, meaning one lab states that they have higher alkalinity in their water, so they require a different methodology for treating and measuring their products.

Or it can just come down to manpower. One lab states that their quality technicians are spread too thin. So, while another facility’s techs might do 12 checks, this lab does only eight of those checks, and the remaining four are performed by shop floor operators…so there’s this obvious division of labor.

You can see where this is going. We talk to the various groups at an organization, and they tell their disparate stories of how they conduct their daily affairs. Then they talk to each other as they try to decide on standards and discover just how differently they do things. And it’s a tough ball of yarn to untangle.

So, it’s helpful to know and understand the benefits of reaching consensus, of standardizing wherever and whenever you can. Then, when you run into these difficulties, you can see how important it is that you come to an understanding and standardize things within your organization.

And, believe me, the benefits of standardization in manufacturing far outweigh the temporary headaches.

So, there we have it. The benefits of standardization in manufacturing. A standardized system costs less, takes less time to deploy, gives you greater insight, and takes less to maintain and expand. The call to arms to stand firm and make it happen. In Part II of this short series, we’ll look at the challenges that organizations face when they try to standardize, and what can happen when they fail to standardize.