A family-owned company, Hans Kolb Wellpappe GmbH & Co. KG, a leading German specialist in manufacturing corrugated products, has been a long-time user of many of the Kiwiplan Manufacturing Execution System (MES) suite of products. Recently they decided they needed to electronically record quality test results in a way that was rapid, accurate and easy to access. They turned to the Kiwiplan Quality Management System (QMS) module for the solution.

Oliver Bohr, Quality Manager for Hans Kolb, says, “For years we have had control of production scheduling, feedback and reporting, but the QMS module fills an obvious gap in our daily production processes. The primary task of our operators is to provide quality goods, but a secondary task is to provide the production and quality information. This information ensures the best quality product is delivered to our customers.” Mr Bohr continues, “Historically we have used a paper system for recording quality checks which is time consuming and prone to inaccuracy. Ensuring that the quality checks are done at the correct time intervals is challenging when done on paper. Valuable information was often filed and utilised only if a quality issue occurred. We wanted to continue to reduce our reliance on paper work and have real-time, event-driven testing. The QMS module from Kiwiplan gives us that ability.”

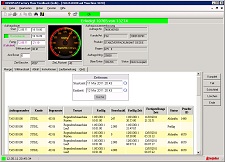

The fact that QMS has flexible test creation and exists within the operator’s screen speeds the process of running quality checks and collecting quality data. This allows the operator more time to run the machine. Hans Kolb reports that QMS training was simple and easy to do.

Hans Kolb’s corrugated plants in Memmingen and Buxheim (Germany) are running QMS and have achieved their stated goals, according to the company, and their third corrugated site in Haiterbach (Germany) will be implementing QMS in the near future.

Mr Bohr summarises the key strengths of QMS : “First, it’s flexible in the type of tests that can be created. Second, it seamlessly ties into the other Kiwiplan products, which reduces the amount of screen changing. Third, it enforces testing at the correct time, which means that if a quality issue arises, it will be found early.” The result is accurate and timely quality results that still allow operators to focus on the main responsibility – operating the machines.