Kiwiplan announces the availability of the new Sheet Counter Link to make delivery and billing errors, shrinkage, and costly and unwarranted credits a thing of the past for sheet feeders. A Kiwiplan Sheet Counter Link eliminates these problems, resulting in precise and reliable unit counts, accurate delivery and billing information, elimination of over and short deliveries, and reduction in paper shrinkage and credits due to reported shortages.

How Kiwiplan Sheet Counter Link Works

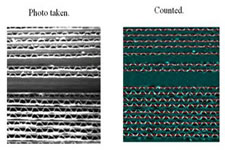

Kiwiplan produces a bar-coded load tag at the stacker for each unit produced at the corrugator. At the strapper, a bar code scanner scans the tag on each unit, determines the unit ID, and transmits the unit ID to Kiwiplan. Kiwiplan then automatically sends unit information, such as Unit #, flute, number of stacks in a load, and job number to the OpSigal sheet counter. OpSigal scans the unit and sends the accurate unit count to Kiwiplan while storing the unit image and count, thus providing irrefutable evidence of unit counts.

The strapper operator inspects units, checks the over/under run allowance, makes adjustments, validates unit counts, and submits counts.

Kiwiplan then transmits unit details to finished goods management and the billing systems. Accurate counts can then be printed directly on the Bill of Lading, resulting in increased delivery and invoicing accuracy.